Product Description:

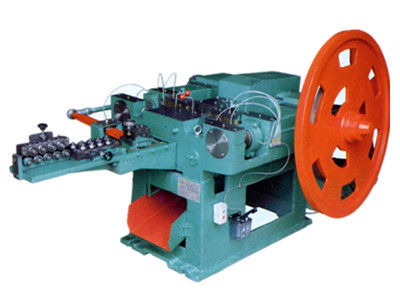

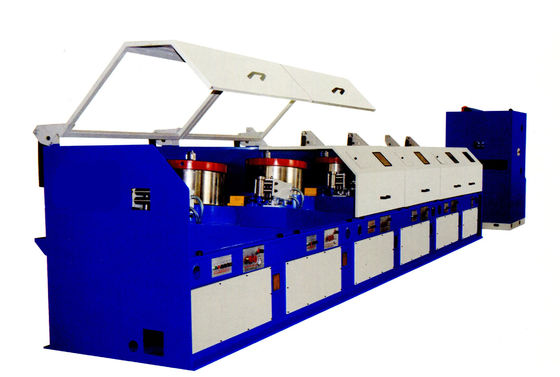

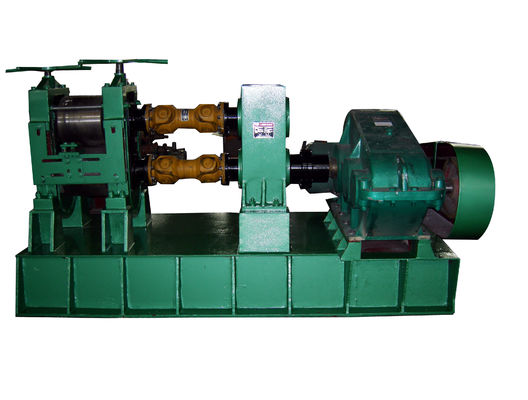

Wire Drawing Machines are essential wire processing equipment used in various industries for producing high-quality wires. These machines, also known as Wire Draw Machines or Wire Manufacturing Equipment, are designed to efficiently draw wire through a series of dies to reduce the diameter and improve the surface finish of the wire.

The Wire Drawing Machines are equipped to operate at different voltages, including 220V, 380V, and 440V, making them versatile and suitable for various power supply requirements. They can also work seamlessly at both 50Hz and 60Hz frequencies, ensuring compatibility with different power systems.

Featuring a fan power of 30W, these Wire Drawing Machines are equipped with efficient cooling systems to maintain optimal operating temperatures during prolonged use. The fan power ensures proper ventilation and heat dissipation, contributing to the overall performance and longevity of the machines.

With a single working position for roll positioning, these Wire Drawing Machines are designed for ease of operation and enhanced efficiency. The single working position allows for a streamlined wire drawing process, enabling operators to control and monitor the wire drawing operation effectively.

Guiding wheel material is a crucial aspect of Wire Drawing Machines, and these machines are engineered with stainless steel guide wheels. Stainless steel is known for its durability, corrosion resistance, and smooth surface finish, making it an ideal material for guide wheels in wire drawing applications. The stainless steel guide wheels ensure consistent wire guiding and reduce friction during the wire drawing process.

Features:

-

Product Name: Wire Drawing Machines

-

Voltage: 220V/380V/440V

-

Guide Wheel Material: Stainless Steel

-

Usage: Wire Drawing Lubricant

-

Frequency: 50Hz/60Hz

-

Showroom Location: Indonesia, Bangladesh, Malaysia

Technical Parameters:

|

Roll Position

|

Single Working Position

|

|

Frequency

|

50Hz/60Hz

|

|

Cooling System

|

Water Cooling

|

|

Guide Wheel Material

|

Stainless Steel

|

|

Voltage

|

220V/380V/440V

|

|

Fan Power

|

30W

|

|

Power Source

|

Electricity

|

|

Marketing Type

|

Hot Product

|

|

Usage

|

Wire Drawing Lubricant

|

|

Showroom Location

|

Indonesia, Bangladesh, Malaysia

|

Applications:

Wire Drawing Machines are essential wire processing equipment used in a variety of industries for manufacturing wires of different diameters and materials. With guide wheels made of stainless steel, these machines ensure smooth wire drawing operations, making them suitable for a wide range of applications.

These machines are designed to operate at a frequency of 50Hz/60Hz, making them compatible with most power supplies. The power source for Wire Drawing Machines is electricity, providing a reliable and consistent source of energy for continuous wire drawing processes.

Equipped with a water cooling system, Wire Drawing Machines effectively dissipate heat generated during the wire drawing process, ensuring consistent performance and prolonging the machine's lifespan. This feature makes them ideal for high-volume production environments where cooling is essential for maintaining operational efficiency.

Featuring a single working position for roll positioning, Wire Drawing Machines offer ease of operation and maintenance. This design simplifies the wire drawing process, making it suitable for various wire manufacturing applications.

Wire Drawing Machines are commonly used in wire manufacturing facilities, metalworking workshops, and industrial plants that require efficient wire making machinery. Their versatility, reliability, and performance make them a valuable asset in producing wires for various industries, including automotive, construction, electronics, and telecommunications.

Customization:

Enhance your wire processing capabilities with our Product Customization Services for Wire Drawing Machines. Tailored for Wire Drawing Lubricant usage, our customization options include:

- Guide Wheel Material: Stainless Steel

- Fan Power: 30W

- Frequency: 50Hz/60Hz

- Voltage: 220V/380V/440V

Upgrade your Wire Processing Equipment with these customizable features to meet your specific wire manufacturing needs.

Support and Services:

Our Wire Drawing Machines are designed to meet the highest standards of quality and performance. Our Product Technical Support team is dedicated to providing assistance with any technical issues that may arise. Whether you need help with machine operation, troubleshooting, or maintenance, our team is here to help.

In addition to our technical support services, we also offer a range of services to ensure that your Wire Drawing Machine operates at its best. Our services include machine installation, training programs for operators, and regular maintenance and servicing to keep your machine running smoothly.

Packing and Shipping:

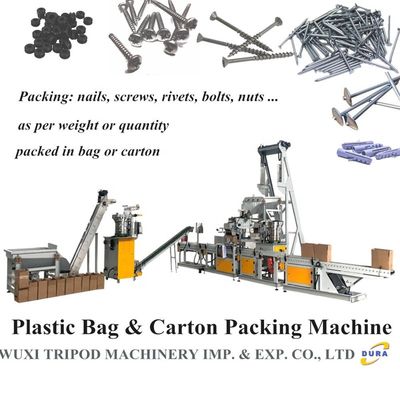

Product Packaging for Wire Drawing Machines:

Each Wire Drawing Machine is carefully packed in a sturdy cardboard box to ensure safe transportation and delivery.

Shipping Information:

Shipping Method: Standard shipping

Shipping Time: 5-7 business days

Shipping Cost: Calculated at checkout based on location and order size

FAQ:

Q: What is a wire drawing machine?

A wire drawing machine is a piece of equipment used to pull wire through a series of dies to reduce its diameter for various applications.

Q: What types of wires can be processed using a wire drawing machine?

Wire drawing machines can process various types of wires including steel, aluminum, copper, and other materials depending on the machine's specifications.

Q: What are the key features to consider when choosing a wire drawing machine?

Key features to consider include the machine's wire diameter range, drawing speed, motor power, number of dies, and overall build quality for durability and efficiency.

Q: How is the wire drawing process beneficial?

The wire drawing process helps improve the wire's mechanical properties, surface finish, and dimensional accuracy, making it suitable for various industrial applications such as manufacturing of cables, wires, and other products.

Q: How can I maintain a wire drawing machine for optimal performance?

To maintain optimal performance, regular cleaning, lubrication of moving parts, checking and replacing worn dies, and scheduling preventive maintenance are essential steps for ensuring the longevity and efficiency of a wire drawing machine.

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!